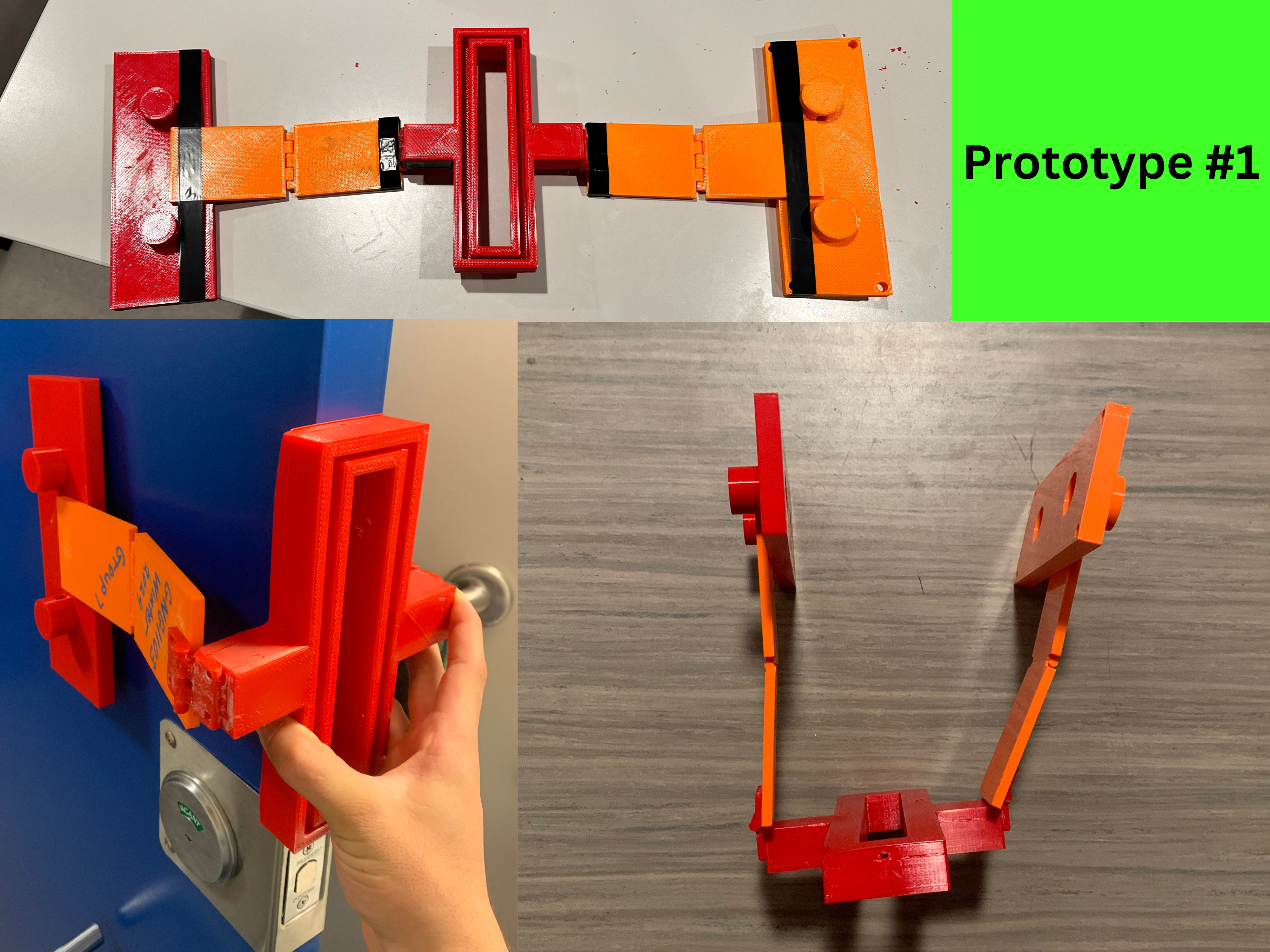

Prototype #1

Test Plan

- Basic structure, hinges and mechanical functionality completed

- All 3D components created on OnShape has been printed and assembled

- Basic structural integrity should be accounted for

Results

- All components were successfully assembled through the use of super glue, hot glue and other adhesives.

- Moving forward, we will be to stay away from weak bonding methods and strive for more permanent solutions that will improve performance.

- Certain components were printed using 70% infill. This led to certain structural issues that will be corrected by the next prototype. Through using 100% infill, we can ensure that the jig will be strong enough to withstand years of use.

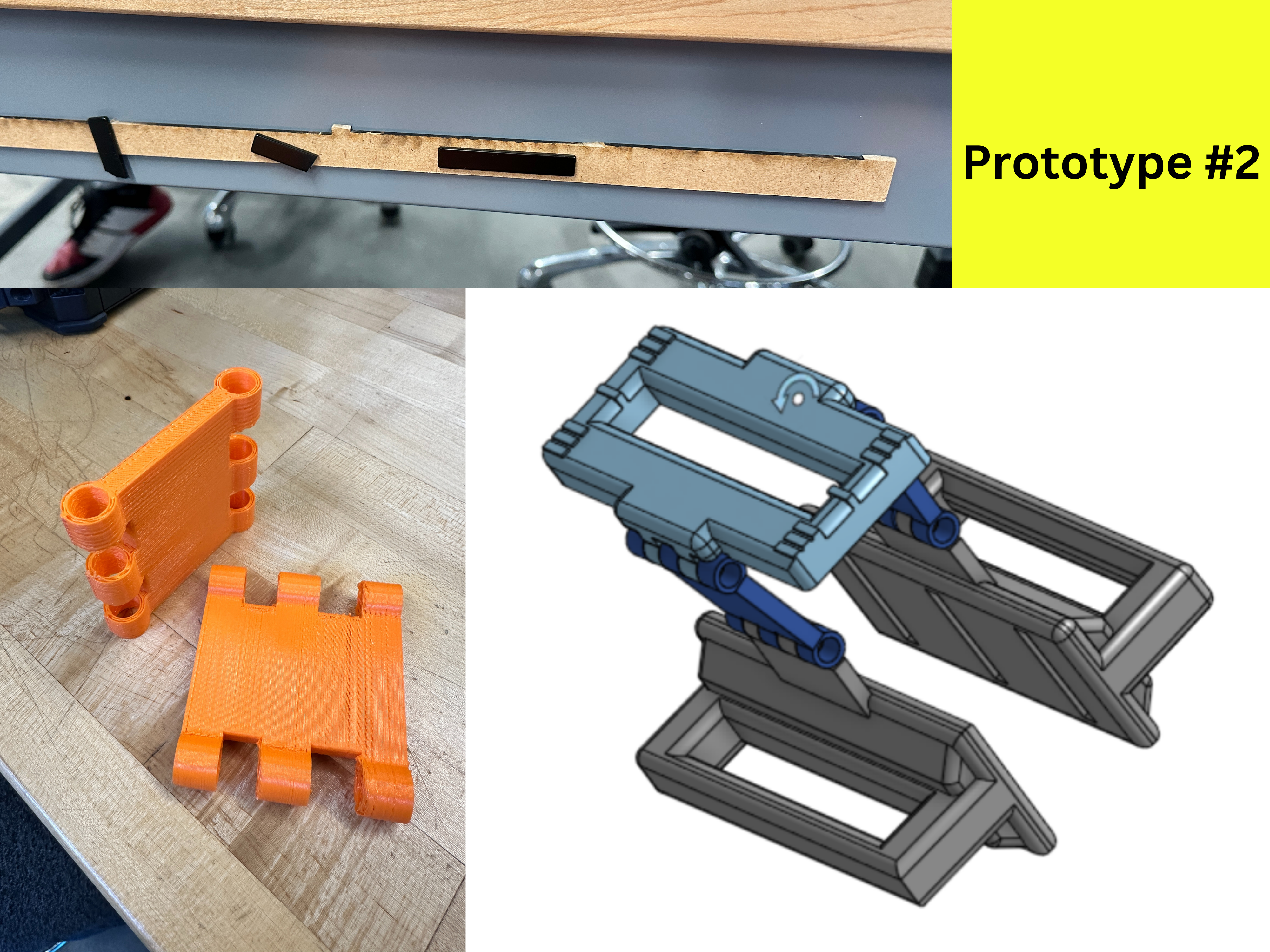

Prototype #2

Test Plan

- Changing the design from utilizing electromagnets to neodymium

- Adding handles so that the user can easily manipulate the clamping section of the jig

- All jig components will be 100% infilled to allow for maximum structural integrity

- Testing if neodymium magnets will penetrate the wood veneer

Results

- Jig is significantly sturdier and can withstand further wear and tear

- Moving forward, we will look into using metal nuts, bolts and washers to put the hinges together. This way, we can ensure the strength of the piece.

- Use of three neodymium magnets will produce a strong enough magnetic force to hold onto the steel door through a 3/32” wood veneer.

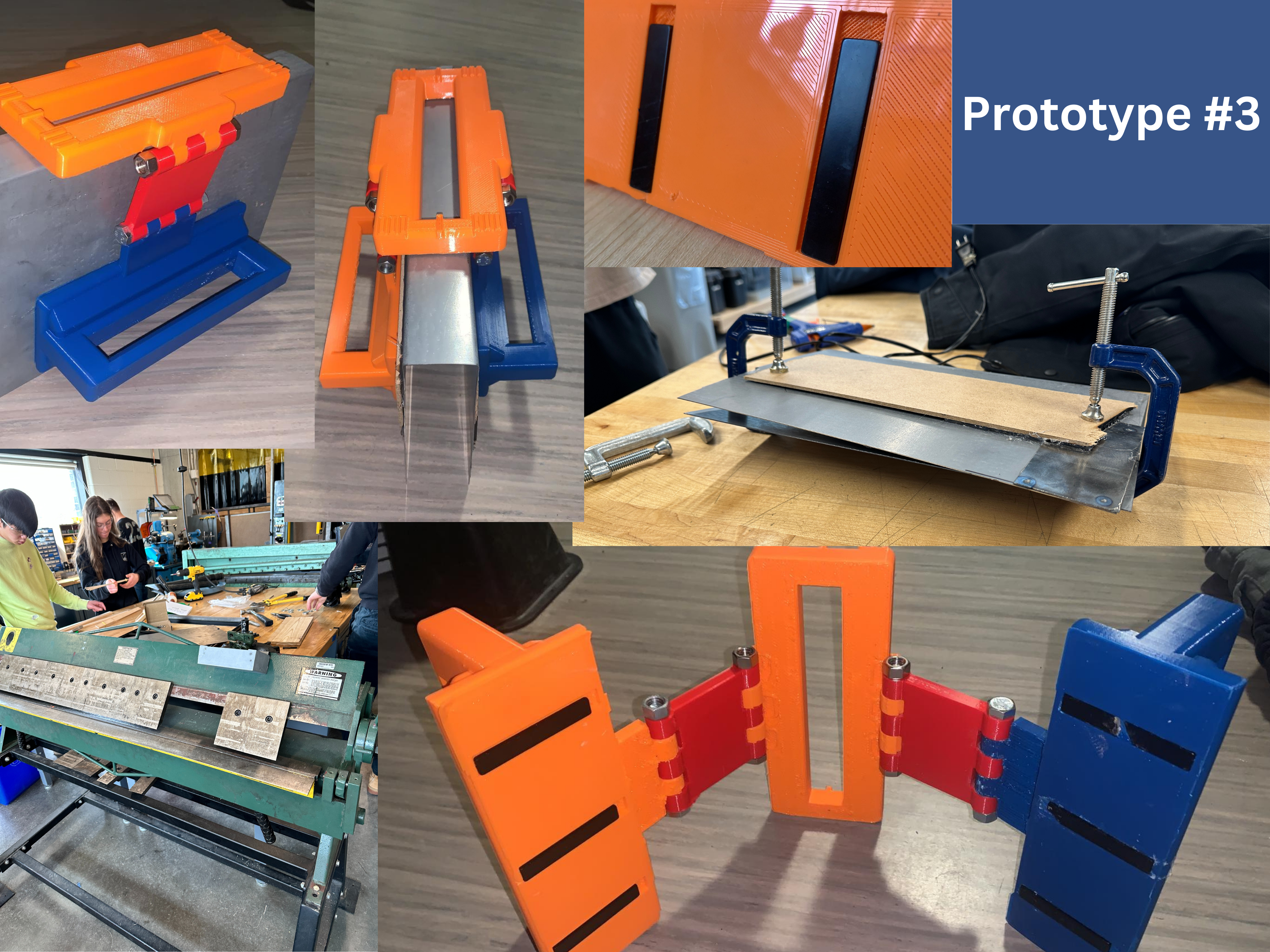

Prototype #3

Test Plan

- Will aim to making the jig the same colour

- Ensure that the longevity of our design is correct

Results

- Jig is currently a mismatch of colours, thus will look into spray painting the body to match.

- Magnets hold the jig in place and are adequate for our implementation

- 30% lightning infill seems to have enough structural integrity for the magnet holders of the jig design