Magnet Testing

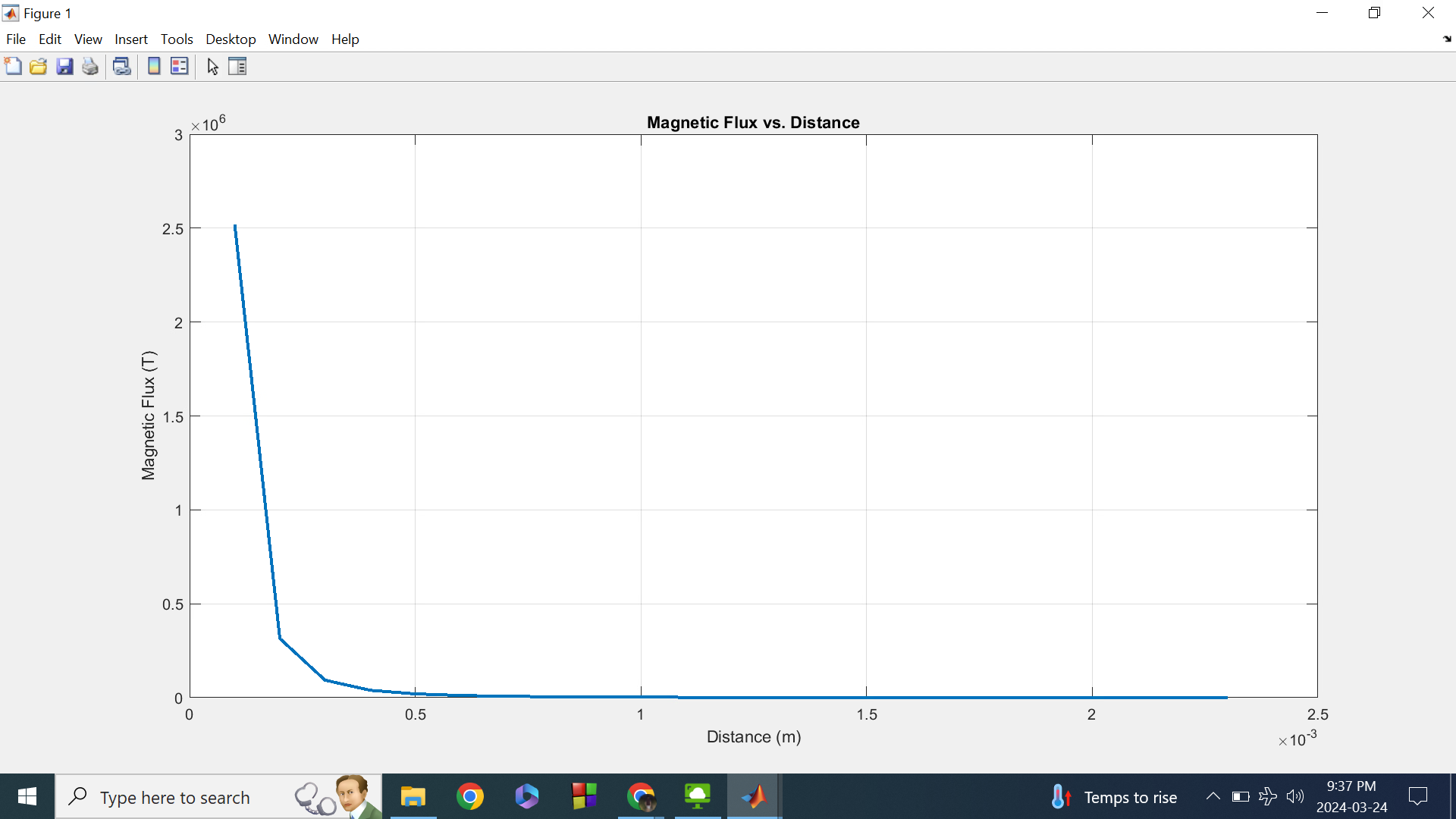

9V – 50 N Electric Lifting Magnet

Pros

- Overall size: 25 x 20 mm

- $ 13.49 + tax

Cons

- Lack of penetrability through 1/8” MDF

12V – 400 N Electric Lifting Magnet

Pros

- Can penetrate through 1/8” of MDF

Cons

- $ 17.99 + tax

- Overall size: 49 x 22 mm

- Use of three neodymium magnets will produce a strong enough magnetic force to hold onto the steel door through a 3/32” wood veneer.

Neodymium Bar Magnets

Pros

- Can penetrate through 1/8” of MDF

- Replaces the wiring through the jig

Cons

- Needs to be handled with care

Hinge Testing

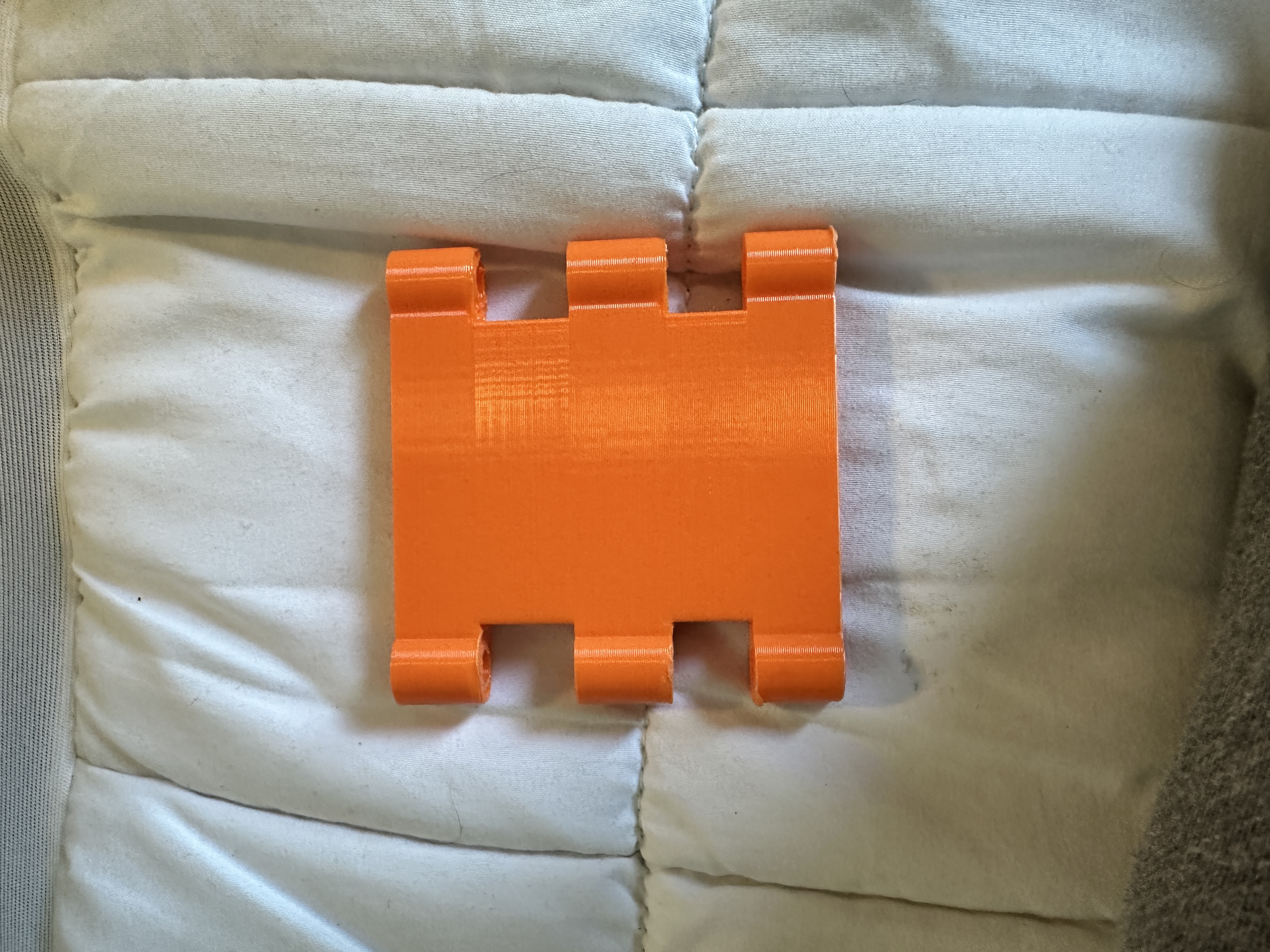

3D Printed PLA Hinges (Friction fit)

Pros

- Prints in place, easy to manufacture

Cons

- Not securely mounted onto the rest of the components

- Friction fit wears out

- Each layer was difficult to print

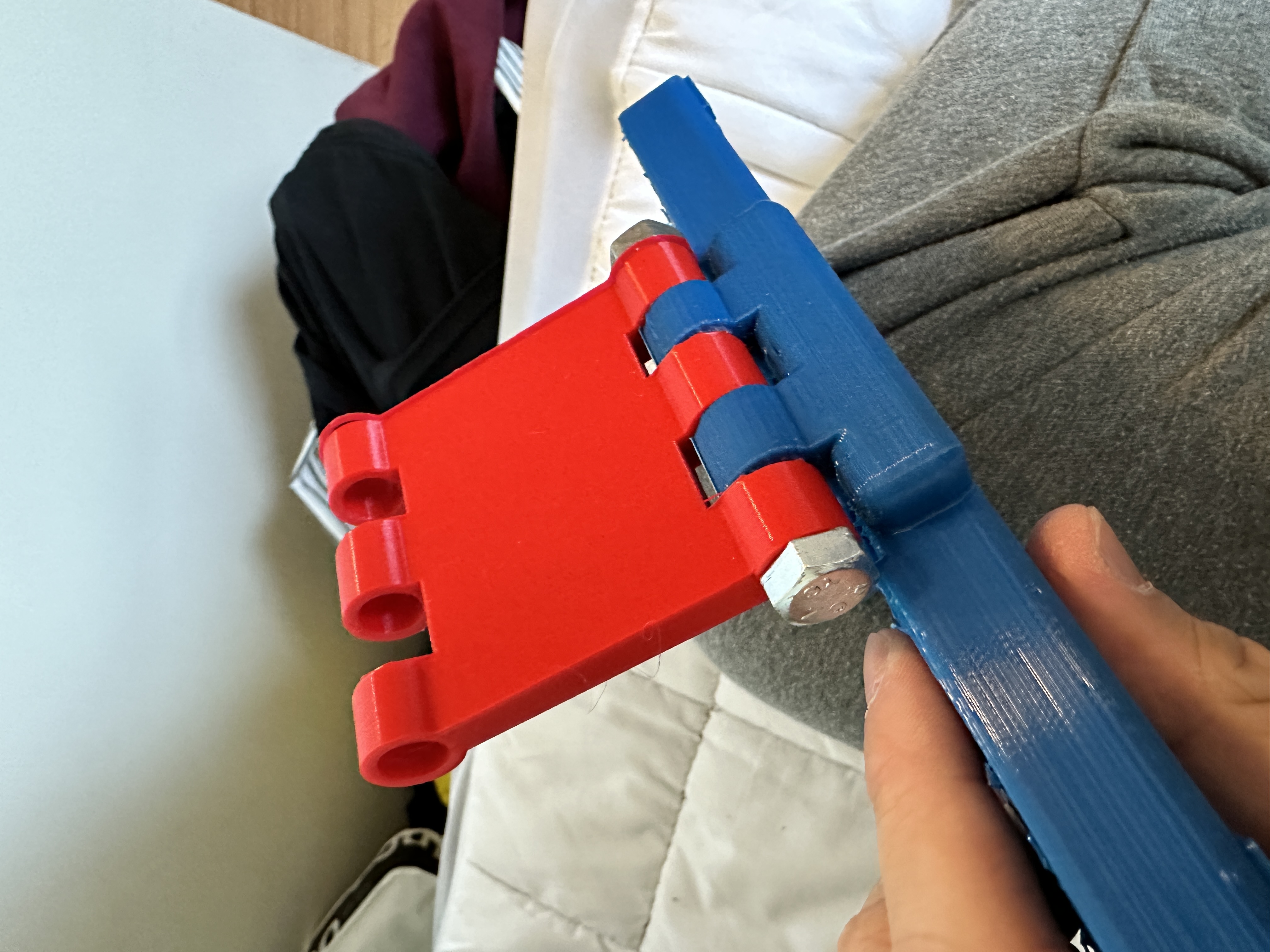

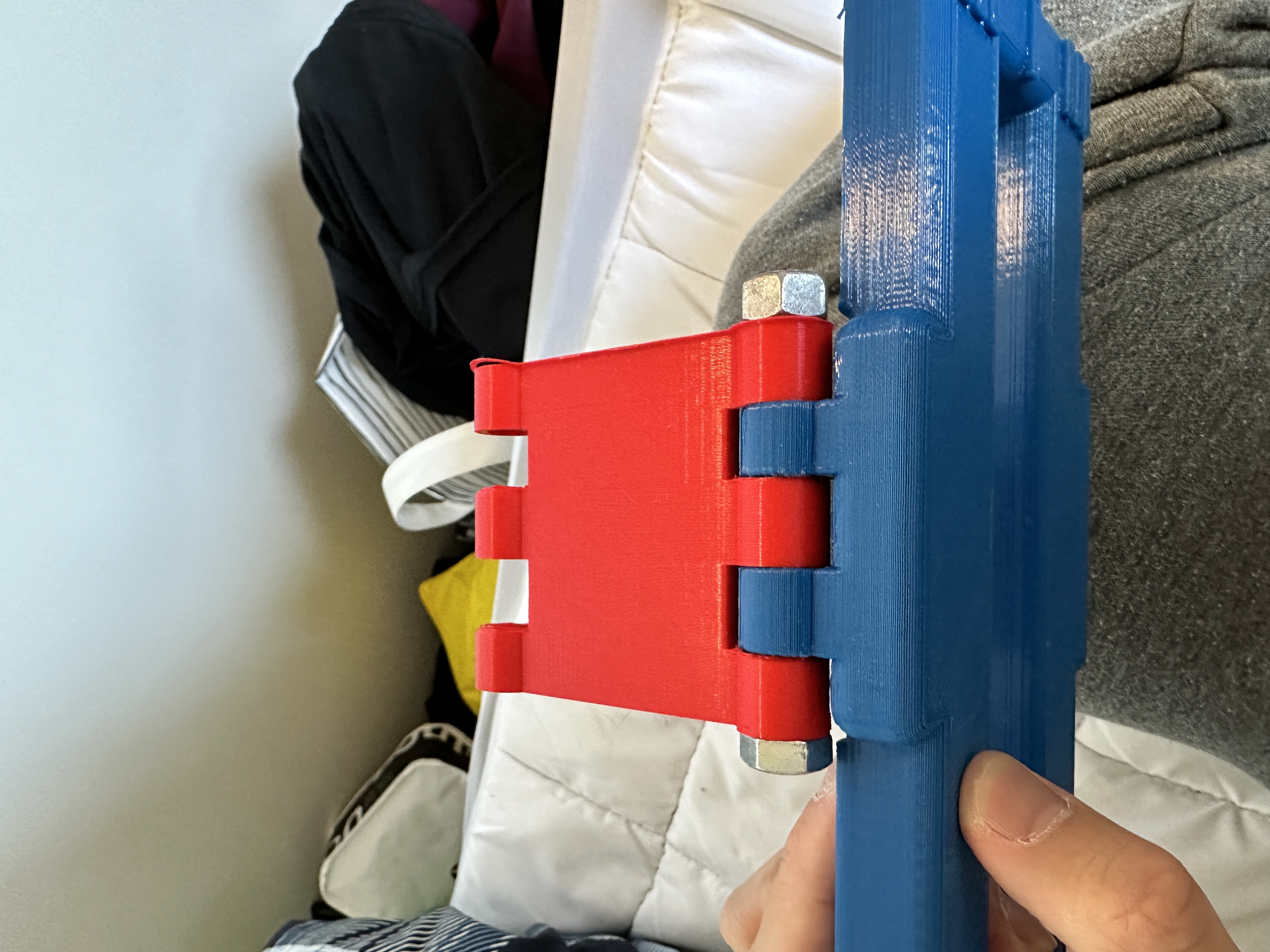

Hinges (Bolt + Nut)

Pros

- Moving parts will not wear out by friction

- Can be disassembled in the event of a component needing repair

- 100% infill makes the component sturdy

Cons

- Getting the hinge to move when first printed requires an adequate amount of force

Infill Testing

Hinge Midpiece (Lightning infill pattern)

Pros

- Printing time was reduced, even at 100% infill

Cons

- Sections that did not have the hinge were hollow

- Would not survive day-to-day wear and tear

Hinges (Bolt + Nut)

Pros

- Solid and feels higher quality

- Won’t break when pressing into it

Cons

- Longer print time

- More filament used